Category: FIBRES

Country: Germany

Authors: Juliana Martins de Souza e Silva, Ralf Wehrspohn

Microstructure-based Materials Design – mikroMD, Martin-Luther University Halle-Wittenberg, Germany

Xiaojian Liao, Seema Agarwal, Andreas Greiner

Macromolecular Chemistry and Bavarian Polymer Institute, University of Bayreuth, Bayreuth, Germany

Mohsen Samadi Khoshkhoo, Fang Zhou

Carl Zeiss Microscopy GmbH, Oberkochen, Germany

Date: July 2020

Introduction

Spider dragline silk has remarkable mechanical properties. It is highly stronger and tougher than steel on an equal weight basis, however, lighter, thinner and more flexible than steel. If it were possible to harvest spider silk commercially it could have been used for high-tech, commercial and consumer applications, such as bridge cables, aerospace components, biodegradable water bottles or antimicrobial medical devices based on its exceptional, superior properties. However, today there is no known way to produce spider silk in commercial quantities, because spiders are cannibalistic, they cannot be raised in concentrated colonies to produce silk. Furthermore, dragline spider silk is also known for its unique combination of strength and toughness. But this combination has been hard to replicate in synthetic fibers, since there is an intrinsic conflict between high strength and high toughness in materials science.

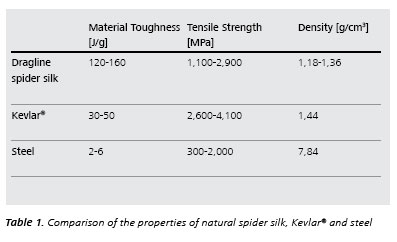

As shown in the Table 1, dragline spider silk is even tougher than Kevlar®, which is currently one of the strongest polymer materials known.

To push the limits of what is possible, scientists are trying to find a way to produce synthetic materials with a strength and toughness comparable to that of spider silk by designing an innovative microstructure of synthetic fibers. Therefore, microscopic characterization of such microstructure using SEM and XRM is necessary to understand the link of microstructure, process and property. In this application note, microscopic characterization of the synthetic fibers using ZEISS FESEM and XRM is introduced which helps to optimize the manufacturing process of such synthetic strong and tough polymer fibers.

To push the limits of what is possible, scientists are trying to find a way to produce synthetic materials with a strength and toughness comparable to that of spider silk by designing an innovative microstructure of synthetic fibers. Therefore, microscopic characterization of such microstructure using SEM and XRM is necessary to understand the link of microstructure, process and property. In this application note, microscopic characterization of the synthetic fibers using ZEISS FESEM and XRM is introduced which helps to optimize the manufacturing process of such synthetic strong and tough polymer fibers.

Polymer Fiber – Stronger and Tougher than Steel

Recently Liao et al. [1] successfully developed a new type of polymer fibers composed of multi-fibrillar polyacrylonitrile yarn with a toughness of 137 ± 21 J/g in combination with a tensile strength of 1236 ± 40 MPa. The nearly perfect uniaxial orientation of the fibrils by heat stretching, annealing under tension in the presence of linking molecules, is essential for the yarn’s notable mechanical properties. This underlying principle can be used to create similar strong and tough fibers from other commodity polymers in the future and could be used in a variety of applications in areas such as biomedicine, satellite technology, textiles, aircrafts, and automobiles [1].

Microscopic Characterization of Polymer Fiber

As reported in [1] the stretched electro spun yarn was annealed at certain temperatures under tension, which leads to overall properties comparable to those of spider silk. Microscopic characterization shows that the small fibers are quite well aligned and cross-linked together via interconnecting molecules after an optimized annealing and tension process. Both electron and X-ray microscopy are used to characterize the morphology of the novel polymer fibers.

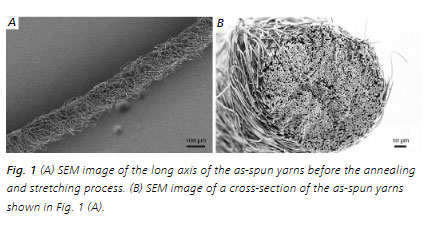

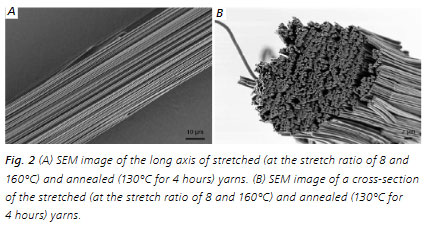

As shown in the SEM pictures taken using ZEISS FESEM (LEO 1530), the as-spun yarn has an average diameter of 130± 12 μm and consisted of ~3000 non-oriented individual fibrils with 1.17 ± 0.12 μm diameter before annealing and stretching processes (Fig.1 (A), (B)). Heat stretching of the yarns for several minutes results in their manifold elongation accompanied by a change in the macroscopic appearance (Fig.2 (A)) and the alignment of the fibrils in the yarns (Fig.2 (B)).

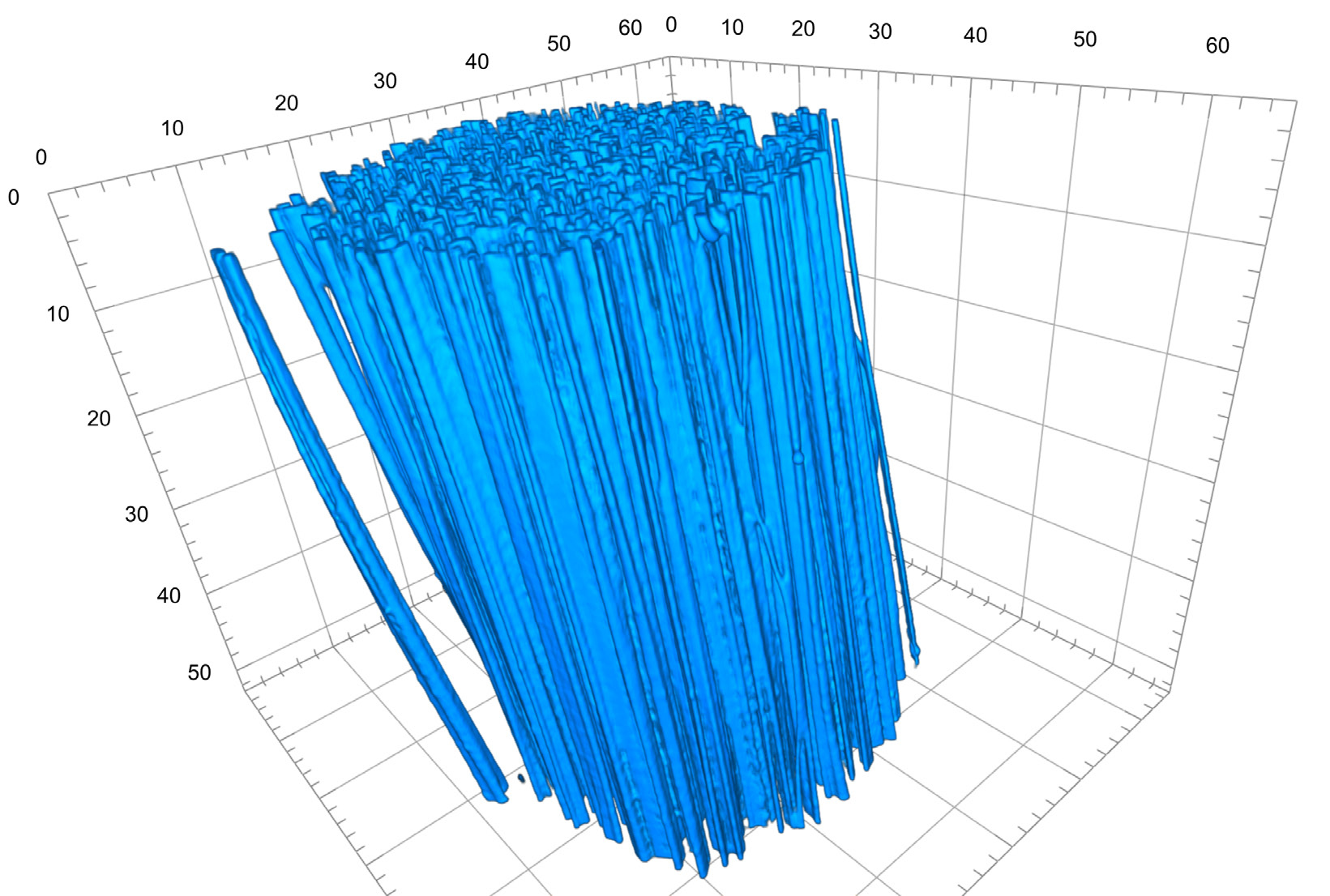

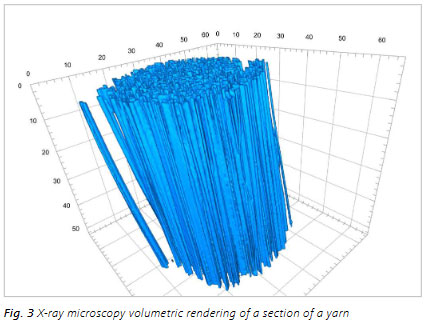

3D X-ray imaging [2] by means of ZEISS Xradia Ultra 810 X-ray microscope reveals the uniform orientation of the fibrils and enables the precise measurements of the diameters of single fibril as well as stretched and unstretched yarns. The tortuosity estimation, calculated using the 3D images, is equal to 1.00 for stretched yarns (at the stretch ratio of 8 and 160°C) and agrees well with the uniform orientation of the fibrils [1]. Fig. 3 shows a volumetric reconstruction of a section of a yarn. Fig. 4 shows one fibril from one yarn and Fig.5 a closer look inside of a yarn [2].

Conclusion

The ZEISS FESEM LEO 1530 is based on the proven Gemini technology with very high resolution and highest sample flexibility in surface sensitive imaging and analysis. It delivers unique contrast and is very suitable for beam sensitive samples like polymers, just because of its unique low-kV imaging performance.

ZEISS Xradia Ultra is a laboratory-based nanoscale 3D X-ray microscope (XRM) which enables non-destructive 3D or 4D tomography with a resolution in the sub-micrometer range for polymer samples. ZEISS Xradia Ultra delivers uniquely strong phase contrast using a Zernike-type phase plate to enhance the high-resolution imaging of low Z materials, such as poly-mers. The unique phase contrast approach has enabled the characterization of the nanostructure of the synthetic polymer fibers in this work.

Both a ZEISS FESEM and XRM were successfully applied to characterize the morphology and to understand the effects of the annealing and stretching process in order to optimize the overall properties of polymer fibers. Various samples such as protein fibers, porous materials, catalysts and drugs, and so on can be characterized using these microscopic methods to visualize 3D microstructures of samples and to estimate structural parameters using software analyses.

References

[1] X.J. Liao, et al. Science 2019, Vol. 366, Issue 6471, pp. 1376-1379, DOI: 10.1126/ science.aay9033

[2] ZEISS Blog: https://blogs.zeiss.com/microscopy/en/x-ray-microscopy-for-novel-polymeric-materials

Copyrights © 2025 GLOBAL TEXTILE SOURCE. All rights reserved.