Category: SUSTAINABILITY

Country: India

Region: Asia

By GTS NewsDesk

6th February, 2024

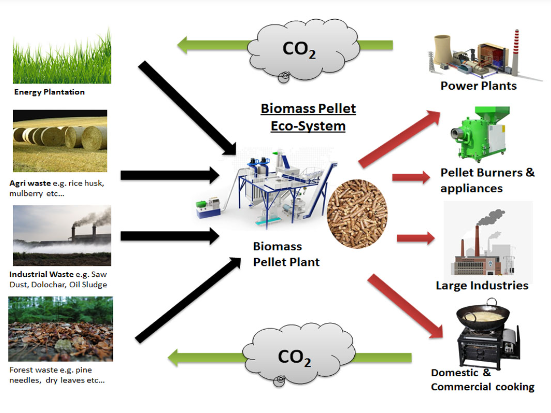

Biomass pelletizing is a process that involves the conversion of biomass materials into pellets. These pellets are typically small, cylindrical shapes and are used as a renewable energy source. Biomass refers to organic materials derived from plants and animals, and biomass pelletizing is a sustainable way to utilize these materials for energy production.

The process of biomass pelletizing typically includes the following steps:

1. Feedstock Preparation:

Biomass feedstock can include various materials such as wood, agricultural residues, energy crops, and organic waste. Before pelletizing, the biomass needs to be prepared, which may involve shredding, chipping, or grinding to reduce the size and make it suitable for the pelletizing process.

2. Drying:

Biomass materials usually contain some level of moisture, which needs to be reduced before pelletizing. Drying the biomass helps improve the efficiency of the pelletization process and ensures the quality of the pellets.

3. Pelletizing:

The dried biomass is fed into a pellet mill, where it undergoes compression and extrusion through the dried to form pellets. The process involves applying pressure and heat to bind the biomass particles together. The size and density of the pellets can be controlled by adjusting the parameters of the pellet mill.

4. Cooling:

The freshly formed pellets are hot and need to be cooled before storage or transportation. Cooling can be achieved using ambient air or dedicated pellet coolers.

5. Sieving and Grading:

Pellets may go through a sieving or grading process to remove fines and ensure uniform size distribution.

6. Packaging:

The final step involves packaging the pellets for distribution and use. Pellets are commonly packaged in bags or bulk for transportation and storage.

Biomass pellets have gained popularity as a renewable and sustainable alternative to fossil fuels for heat and electricity generation. They can be used in pellet stoves, boilers, and power plants, providing a cleaner and more environmentally friendly energy option. The process of biomass pelletizing contributes to reducing greenhouse gas emissions and promoting the use of biomass as a carbon-neutral energy source.

A collaborative effort is underway to explore effective strategies that can contribute to a more environmentally conscious and resilient future, Eeco Urja Ventures, under the leadership of Amit Jain, has emerged in biomass pelletizing. Specializing in providing an eco-friendly substitute for fossil fuels and traditional wood-based alternatives, the company stands at the forefront of technological innovation and economic viability.

Eeco Urja Ventures has carved a niche for itself by focusing on biomass pelletizing. The biomass and biofuel produced by Eeco Urja Ventures are not limited to a single application. Instead, they cater to a spectrum of industries, including burners, boilers, and furnaces. This versatility positions their products as valuable solutions across various sectors, contributing to a more sustainable and cleaner energy landscape.

One of the key strengths of biomass and biofuel is their cleanliness and user-friendly nature. As clean energy alternatives gain traction globally, Eeco Urja Ventures is providing solutions that not only reduce environmental impact but also simplify the transition to sustainable practices for end-users.

One of the key strengths of biomass and biofuel is their cleanliness and user-friendly nature. As clean energy alternatives gain traction globally, Eeco Urja Ventures is providing solutions that not only reduce environmental impact but also simplify the transition to sustainable practices for end-users.

Despite facing challenges inherent to the renewable energy sector, Eeco Urja Ventures remains optimistic about the future. Anticipating growth in the next six months, the company's confidence may stem from a combination of market trends, technological advancements, and a commitment to addressing environmental concerns. They underscore the biodegradability of biomass fuel, aligning with their commitment to environmental sustainability. Moreover, the potential for cost savings compared to traditional alternatives enhances the appeal of their products in a market increasingly focused on efficiency and economic feasibility.

Copyrights © 2025 GLOBAL TEXTILE SOURCE. All rights reserved.